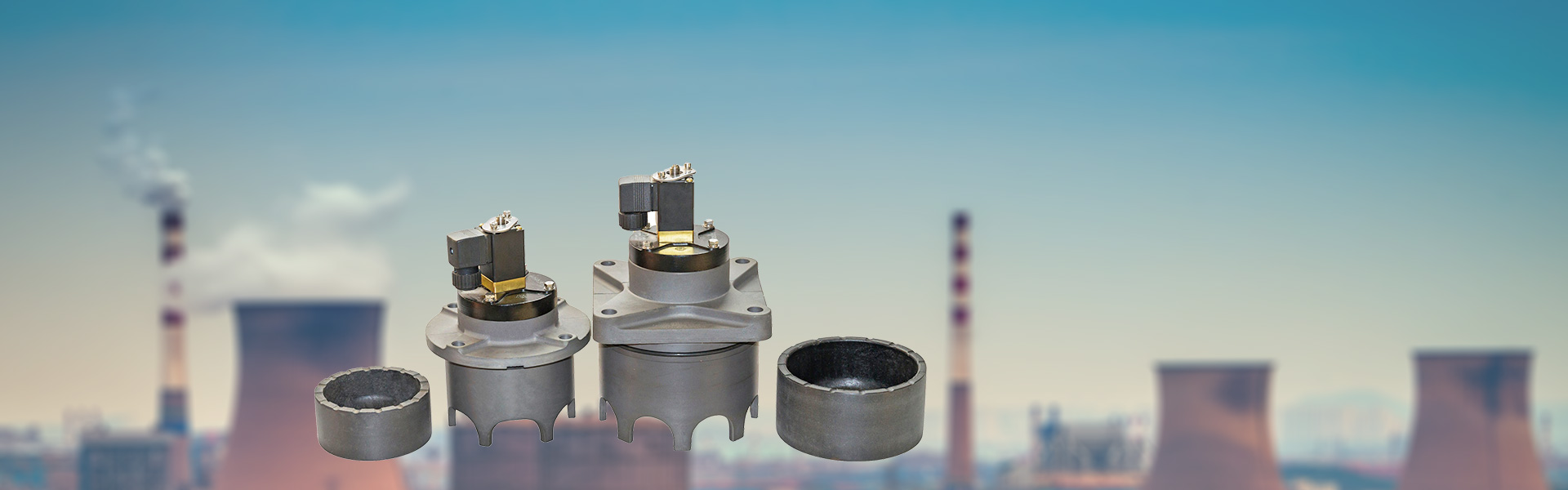

Piston Pulse Fabric Filter Cleaning Valve

Send Inquiry

Qingdao Star Machine is a Piston Pulse Fabric Filter Cleaning Valve production factory, and we are a technology innovation oriented enterprise that integrates product research, development, production, and sales. Our products Piston Pulse Fabric Filter Cleaning Valve are sold in over 40 countries worldwide and have a broad customer base.

The Piston Pulse Fabric Filter Cleaning Valve is the compressed air "switch" of the pulse bag dust removal and blowing system. Under the output signal control of the pulse jet control instrument, the filter bags are sprayed row by row to remove dust and maintain the resistance of the dust collector within the set range to ensure the processing capacity and dust removal efficiency of the dust collector.

Product Parameter (Specification)

| Model NO. | Starmachinechina 135 | Valve Structure | Pilot Membrane Structure |

| Power Supply | DC Solenoid Valve | Usage | Drain, Dust Cleaning |

| Standard | DIN | Application | Industrial Usage |

| Used For | Dust Filter | Trademark | Starmachinechina |

| Specification | 4" | Design static pressure | 15 bar (1500 kPa) |

| Design temperature | 100 °C | Operating pressure | <6bar |

| Operating pressure variation | 3 bar unlimited nos | Operation temperature | 50 °C |

Product Feature And Application

FUNCTION

FUNCTION

Volume A connected to the pressure tank,via the slot between the valvehouse and the plunger.There is same pressure in the volume A as in the pressure tank.

Due to the larger pressurised surface ofthe plunger in volume A,the plunger is pressed towards the pulse pipe and seals between the pressure tank and the pulse pipe.

The volume B is via the solenoid valve connected to the pilot air.The area is larger on pilot air side so the pilot membrane is pressed down towards the top of the valve house and seals off the volume A from the ambient.

Opening

When cleaning is initiated,the solenoid valve closes the connection(a) and opens to ambient(b) which means that volume B is evacuated.

The membrane is pressed upward(c) and the volume A is evacuated through the 2 ports at the outer side of the valve house.

The plunger is rapidly moving upwards by the pressure difference over theplunger.

The compressed air in the pressure tank is released through the pulse pipe as apulse and further on to a row of filter bags.

Closing

The solenoid is closed to ambient and opened to the pilot air.

The pilot membrane is pressed downtowards the seat.

The pressure above the plunger will be equalised to the tank pressure via the slot between the plunger and the horse and the plunger moves down to the pulse pipe and ends the cleaning pulse.

The time for a sequence(start openingto closed valve)is depending on process demands,i.e Volumeof pulse air per pulse and emission guarantees.

Production Process

At Qingdao Star Machine, we understand the importance of Piston Pulse Fabric Filter Cleaning Valve for industries such as power plants, cement plants, glass factories, and metallurgical processing. That's why we offer this product with the aim of exceeding expectations and meeting the unique requirements of these high dust pollution enterprises. By choosing our dust removal valves, you will enjoy higher efficiency, lower maintenance costs, and higher profitability. A comprehensive after-sales service system will solve your usage troubles.