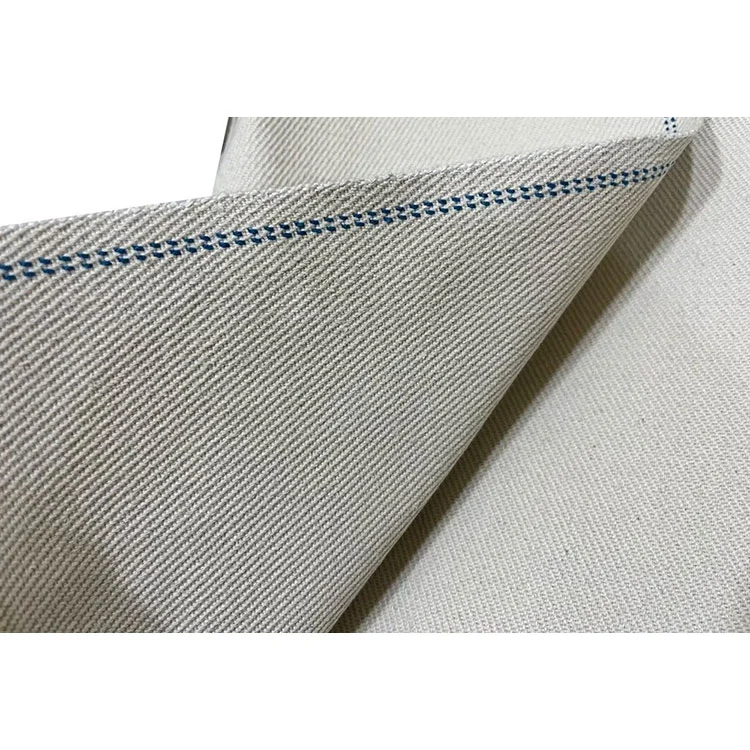

Filter Cloth

Filter cloth can seperate liquids and solids, it plays an important role in the liquid filtration area. Here is the introducition of the common use filter cloth and how to choose them.

Polyester filter cloth

This product is considered to be the world of filter cloth ‘acid-resistant little master’, the temperature of 130 ℃ or less casually used, occasionally soaring to 150 ℃ is also fine. It is divided into two kinds: one is the surface of the smooth filament models, breathable, fast filtration, suitable for the need for rapid treatment of the occasion; the other is a short-fibre models, the fibre wrapped tightly, can block the finer particles, but the breathability will be a little discount. Those belt filter presses in chemical and pharmaceutical factories love to use it, especially when dealing with acidic liquids.

Polypropylene filter cloth

To say that corrosion resistance, polypropylene can definitely rank the top three. Strong acid and alkali are not afraid, but the temperature can not exceed 90 ℃. Monofilament structure of the filter cloth surface is silde, the filter cake a raking off, suitable for high-flow filtration; compound filament structure is like a dense net, specifically to deal with fine particles. Coal washing plant, dye plant those plate and frame filter presses rely on it to live, especially when dealing with corrosive liquids, especially save.

Nylon filter cloth

The wear resistance of this filter cloth is really strong, mining coal washing, metal processing, these ‘hard core’ occasions rely on it to support. Although it can't withstand strong acids, it has no problem with weak acids and alkaline environments. Temperature and polyester is about the same, within 130 ℃ proper. Rubber factories also like to use it as a skeleton material, after all, good flexibility and resistance to manufacturing.

Vinylon filter cloth

Vinylon filter cloth is good in alkaline environments, but it wilts when it meets acid. Do not exceed 100 ℃, especially good water absorption is not easy to deform, ceramic factories, pharmaceutical factories to deal with alkaline liquids commonly use it.

Non-woven filter felt cloth

The nonwoven needle felt cloth is directly made by meltblown fibres, needled into a three-dimensional honeycomb structure, even particles below 1 micron can be caught. The polyester or polypropylene substrate is heat-set and the surface is as smooth as wax. It is indispensable for breweries to clarify wort and electronic factories to purify water systems, and the filtration accuracy of belt filters is directly pulled up to full when they are equipped with this thing.

|

Material |

Structure and Feature |

Temperature resistance |

Chemical stability |

Applicable scenes |

Advantages |

|

Polyester |

Filament/staple fibre, plain or twill weave |

≤130℃ |

Acid and alkali resistant |

Pharmaceuticals, foodstuffs, metallurgy Liquid-solid separation |

High strength, abrasion resistance, good air permeability |

|

Polypropylene |

Monofilament/multifilament, smooth surface or dense mesh |

≤90℃ |

Acid and alkali resistant |

Chemical industry, coal washing, dye filtration |

Corrosion-resistant, easy to clean |

|

Nylon |

Filament weaving, high density twill |

≤130℃ |

Weak acid, alkali resistance |

Coal washing, mineral processing, rubber industry |

Excellent abrasion resistance, good flexibility |

|

Vinylon |

Short fibre plain weave, strong moisture absorption |

≤100℃ |

Alkali resistant, not acid resistant |

Ceramics, pharmaceuticals, sewage treatment |

Low cost, dimensional stability |

|

Non-woven filter felt cloth |

Non-woven three-dimensional structure, heat-setting treatment |

≤150℃ |

Depending on the substrate |

High-precision liquid filtration |

High retention accuracy, excellent permeability |

Filter cloth selection guide:

First, look at the acidity of the liquid (such as strong acid choice of polypropylene), then look at the working temperature (high temperature choice of polyester/non-woven), and finally look at the size of the particles (fine powder choice of non-woven). Of course, we also have to consider the type of equipment - belt filter presses love polyester filament, plate and frame filter presses prefer polypropylene filament, and vacuum drum machines are more compatible with non-woven filter felts!

- View as

High-Performance Antistatic Filter Cloth

Our High-Performance Antistatic Filter Cloth is made with weft yarns that are completely made of antistatic fibre, so it's super effective at resisting static compared to standard filter fabrics. This Chinese supplier SMCC filter cloth is perfect for making fluid bed filter bags and is ideal for high-temperature applications in the pharmaceutical and food processing industries.

Read MoreSend InquiryPPS Needle Felt with PTFE Membrane

SMCC has high quanlity PPS Needle felt with PTFE membrane, has high dust removal efficiency, not easy to be clogged, good surface filtration effect, resistance to persistent high temperature, suitable for working conditions demanding environment, such as chemical plants, coal power plants, and so on. We use the technology of high quality PPS fibres and thermally laminated PTFE membranes to ensure filtration.

Read MoreSend InquiryPolyester Blended Anti-static Needle Felt

SMCC Polyester blended anti-static needle felt are often used for products that need to filter small particles from air or liquids and need to prevent static electricity buildup. These filter felts are often made from special fiber materials to ensure that static electricity does not attract more particles or cause harm to the product during the filtration process.

Read MoreSend InquiryCotton Filter Cloth

Cotton filter cloth, as a filter cloth made of natural materials, is a good choice for environmental protection because of its easy degradability and other advantages. SMCC can customise cotton filter cloth according to customer requirements in satin, twill and plain weave, and samples can be provided.

Read MoreSend InquiryFertilizer Industry PE Liquid Filter Cloth

Fertilizer Industry PE Liquid Filter Cloth is made of high-quality polyethylene (PE) material, which is known for its durability and chemical resistance. This filter cloth is specially designed to handle the challenging conditions prevalent in fertilizer production, including high temperatures, corrosive chemicals, and abrasive particles.

Read MoreSend InquiryWoven Geotextile Fabric

SMCC high quality Woven geotextile fabric can be made from a variety of materials, but the most common materials are usually braided fabrics or yarn blends. Braided geotextiles usually resemble plastic sheeting when finished and the weave can only be seen by looking closely. Whether you need a medium or lightweight woven geotextile fabric depends entirely on the purpose of your construction project. If you are unsure of the type of geotextile you need, please contact our engineers for advice.

Read MoreSend Inquiry