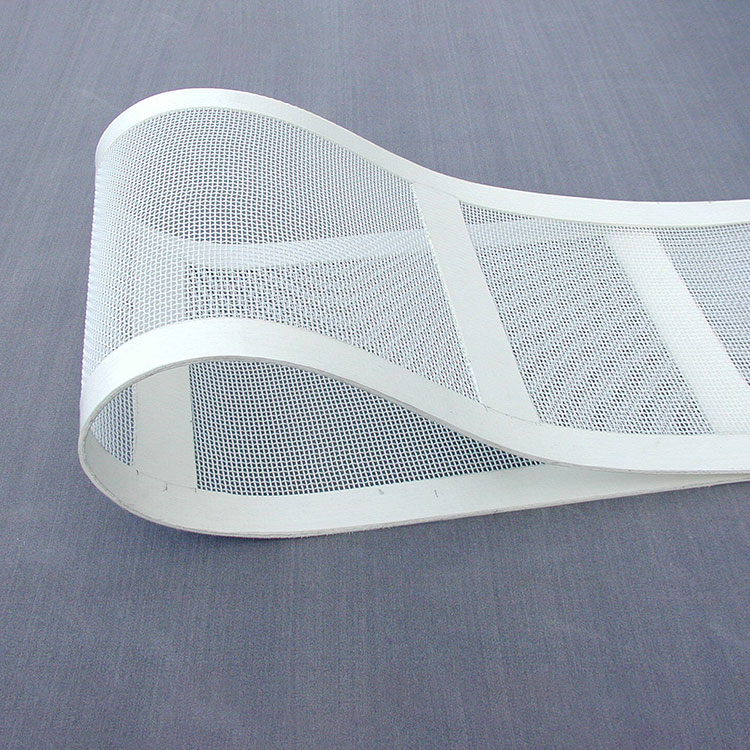

Polyester Filter Conveyor Belt

SMCC provides Polyester Filter Conveyor Belt, it is a high-performance solution designed to meet the rigorous demands of dust and particle control. Made of high-quality polyester, this conveyor belt is highly durable and can withstand harsh environments for a long service life. Its robust construction and superior material make it an ideal choice for enhancing your conveyor system's efficiency and longevity.

Send Inquiry

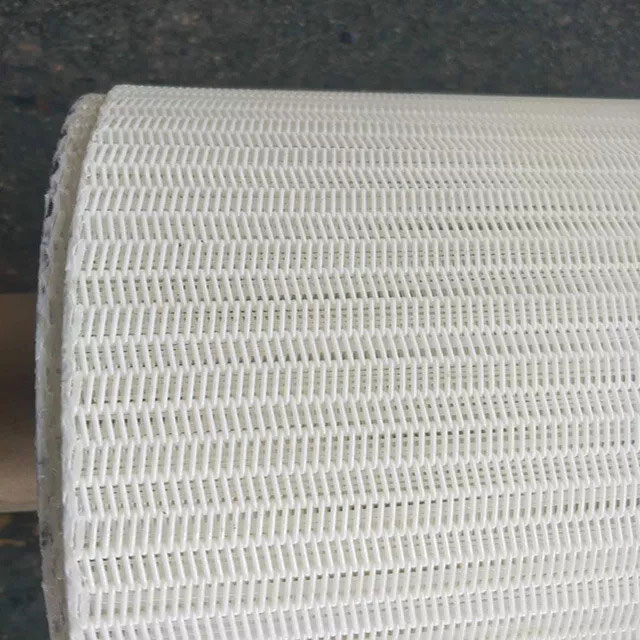

SMCC Industrial polyester filter conveyor belt is a conveyor belt made of polyester fiber as raw material has excellent wear resistance, high temperature resistance, corrosion resistance, and other characteristics, suitable for various harsh industrial environments. Industrial polyester filter mesh is mainly used for material transportation and filtration, completing the screening and separation of materials during the transportation process. This type of conveyor belt typically has high strength and stability, ensuring efficient operation under various conditions.

Product Process

Raw materials → sizing → weaving → cleaning and inspection → primary heat setting → insertion section → secondary heat setting → finished product packaging

Product Advantages

Industrial polyester filter conveyor belt have various advantages such as high filtration efficiency, high strength, wear resistance, high temperature resistance, corrosion resistance, good filtration performance, and easy cleaning, making them suitable for dynamic material filtration and transportation.

Product Parameters

Polyester Spiral Filter Screen

| Item | Model | Permeability(m3/m2h) |

| Big Circle | LGW4×8 | 16500-19500 |

| Medium Circle | LGW3.8×6.8 | 16500-19500 |

| Small Circle | LGW3.2×5.2 | 16500-19500 |

Polyester Filter Belt

| Model | Wire Dia.(mm) | Density/CM | Hole Size | Porosity | ||

| Warp | Parallel | Warp | Parallel | mm | % | |

| CXW25254 | 0.22 | 0.25 | 27-28 | 22-23 | 0.144×0.194 | 17.3 |

| 25274-2 | 0.22 | 0.27 | 27-28 | 18.5-19.5 | 0.144×0.256 | 19.4 |

| 27234-1 | 0.20 | 0.23 | 29.5-30.5 | 23.5-24.5 | 0.133×0.187 | 17.9 |

| 27234-2 | 0.20 | 0.23 | 30-31 | 23.5-24.5 | 0.128×0.187 | 17.5 |

| 27254 | 0.20 | 0.25 | 29.5-30.5 | 21.5-22.5 | 0.133×0.204 | 18 |

| 27274 | 0.20 | 0.27 | 29.5-30.5 | 21-22 | 0.133×0.195 | 16.8 |

| 29234 | 0.20 | 0.23 | 31-32 | 21-22 | 0.177×0.235 | 18.7 |

| 29254 | 0.20 | 0.25 | 31-32 | 20.5-21.5 | 0.177×0.226 | 17.6 |

| 31204 | 0.17 | 0.20 | 34-35 | 29-30 | 0.120×0.139 | 17.0 |

| 25358 | 0.22 | 0.35 | 27.5-28.5 | 18.5-19.5 | 0.137×0.176 | 12.9 |

| 25408 | 0.22 | 0.40 | 27.5-28.5 | 18.5-19.5 | 0.137×0.176 | 12.9 |

| 27358 | 0.20 | 0.35 | 29.5-30.5 | 19-20 | 0.133×0.163 | 12.7 |

| 27408 | 0.20 | 0.40 | 29.5-30.5 | 19-20 | 0.133×0.163 | 12.7 |

Polyester Washing Filter Screen

| Model | Density/CM | Wire Dia.(mm) | Hole Size | Porosity | Intensity | ||

| Warp | Paralle | Warp | Paralle | mm | % | N/CM | |

| Xw18302 | 19.6±0.5 | 14±0.5 | 0.25 | 0.30 | 0.260.41 | 29.5 | ≥400 |

| XW18303 | 19.5±0.5 | 14±0.5 | 0.25 | 0.30 | 0.260.41 | 29.58 | ≥400 |

| XW16302 | 17.5±0.5 | 13.5±0.5 | 0.27 | 0.30 | 0.300.44 | 24.97 | ≥400 |

| XW16302 | 17.5±0.5 | 13.5±0.5 | 0.27 | 0.30 | 0.300.44 | 24.97 | ≥400 |

| XW16304 | 17.5±0.5 | 13.5±0.5 | 0.27 | 0.30 | 0.300.44 | 24.97 | ≥400 |

| XW16404 | 17.5±0.5 | 13.5±0.5 | 0.27 | 0.40 | 0.300.34 | 23.9 | ≥400 |

| XW10504 | 20.5±0.5 | 12±0.5 | 0.50 | 0.50 | ≥1600 | ||

Product Application

Industrial polyester filter conveyor belt are widely used in fields such as brewing, sugar making, chemical industry, food production, mining, steel, coal, ports, power, etc. due to their advantages of high strength, wear resistance, high temperature resistance, corrosion resistance, good filtration performance, and easy cleaning. They are mainly used for material filtration and transportation.

Product Washing and Maintenance

Industrial polyester filter conveyor belt is made from polyethylene terephthalate mono-filament as raw material, which is shaped and processed by warp and weft spinning. It has the characteristics of long service life, light weight, simple mesh setting, corrosion resistance, good elasticity, light screen printing, and large air permeability. Industrial polyester filter mesh is the most ideal equipment for dehydration, molding, and drying in contemporary industry.

I. Installation Procedure

1. Open the polyester filter conveyor belt and measure the length and width of the net with a steel tape measure. Visually inspect the appearance and confirm that it is qualified before use on the machine.

2. Remove the frame from the paper machine and check if there are any hanging marks on the parts that come into contact with the net. Then, cover the net and put it on the machine. The arrow "→" on the net should be marked in the direction of the machine's operation.

3. After the rack is installed, adjust polyester filter conveyor belt surface and tension to 3-3.5kg/cm, start the waterproof machine at a slow speed, and adjust the tension to 4-6 kg/cm when there is no problem on the mesh surface.

4. When stopping the machine, the high-pressure water should be turned off first, otherwise the network will be damaged.When washing the net, it is advisable to use a large liquid with a concentration of 5-10% and a temperature below 40 ℃ for common dirt. It is not allowed to use a wire brush to clean the dirt. After removing the dirt, it should be rinsed with clean water.

II, Precautions

polyester filter conveyor belt is a flammable material, and it is not allowed to use open flames when working near the mesh. Especially during machine maintenance, it is strictly prohibited to burn the mesh due to electrical welding. When using it, do not use too much tension to prevent the guide roller from breaking. The guide roller should be flexible to prevent the mesh from deviating and folding.