Catalytic Filter Bag

The large amount of harmful substances (chemicals such as dioxins and furans) produced in waste incineration are hazardous to human beings and cause great pollution to the environment, which requires us to do better in the dust removal and filtration industry. In response to the harmful substances produced during the incineration of domestic waste, we have upgraded and modernised the technology of dust removal and filtration, and introduced new catalytic filter bags in order to face the majority of customers with high requirements, and to build a sustainable future for mankind.

Send Inquiry

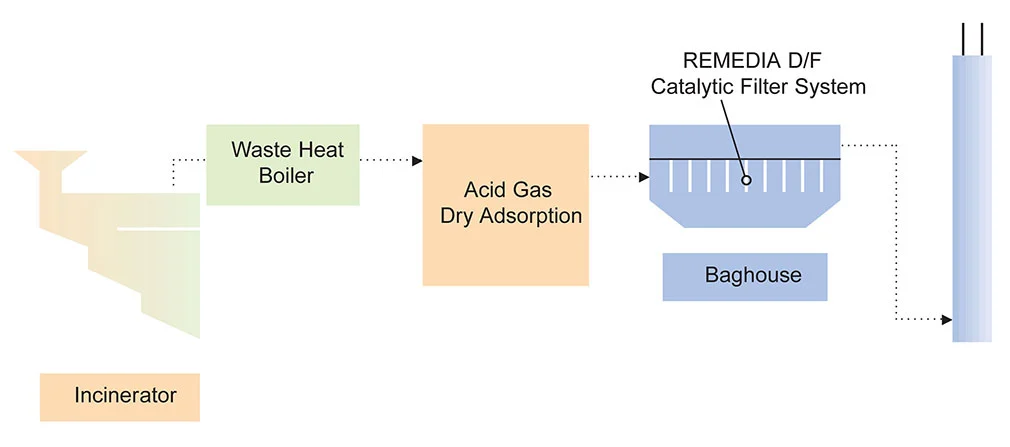

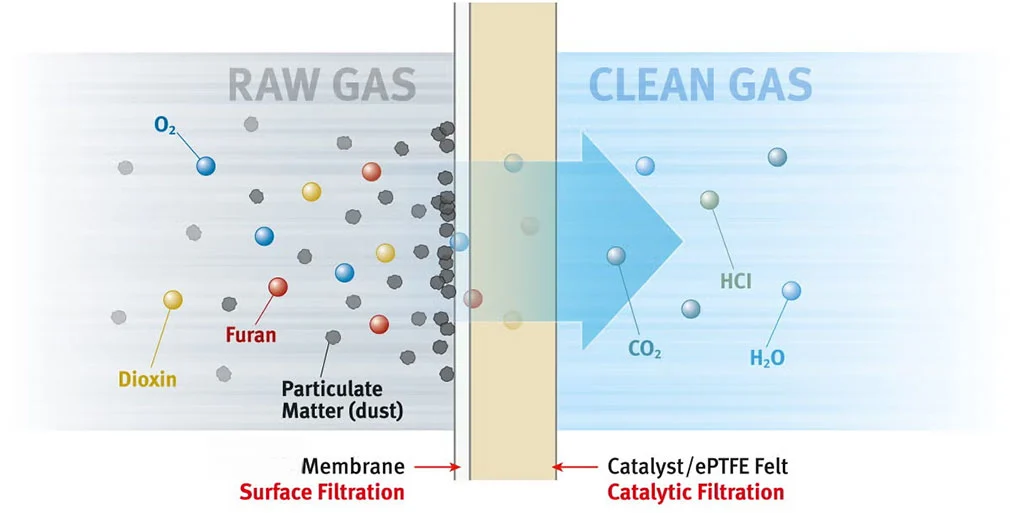

SMCC has developed a unique dioxin control process that can help you reduce emissions from 1.0ng TEQ/Nm3 to 0.1ng TEQ/Nm3 with no additional investment, and can be replaced with a new catalytic filter bag to meet your emission requirements. The dioxin control process integrates two technologies in a system: 'catalytic filtration' and 'surface filtration', consisting of an expanded polytetrafluoroethylene (ePTFE) membrane with a catalytic backing. The backing is a needle-punched structure and the fibres are made of expanded polytetrafluoroethylene (ePTFE) with a catalyst. This composite catalytic felt material is capable of destroying dioxins (PCDD/Fs) completely at 180 degrees Celsius to 260 degrees Celsius. Under the action of the catalyst, dioxin undergoes an immediate oxidative decomposition reaction and is broken down into tiny amounts of CO2, H2O and HCI, and the filtered gas meets environmental standards.

The physical filtration effect of the catalytic filter bag also has a superb performance, the catalytic filter bag surface composite high-density PTFE film to remove sub-micron dust, can block the fine particles penetrate to the bottom of the cloth, the particulate dioxins (PCDD/Fs) in the surface of the filter bag can be effective filtration, only a small portion of the gaseous PCDD/PCDFs through the film into the catalytic felt to be effectively decomposed.