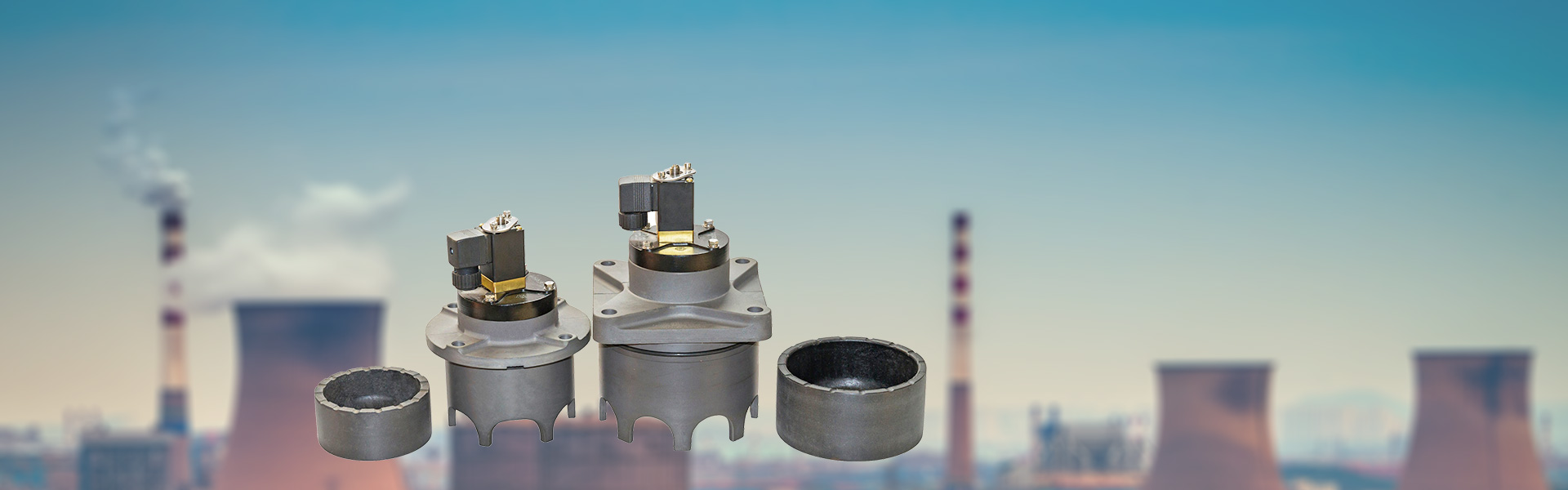

Dust Collector Pulse Jet Valve

Qingdao Star Machine provides V1614718 Dust Collector Pulse Jet Valve, it is based on diaphragm electromagnetic pulse valve and piston mechanism design, adopting embedded structure, with stronger blowing performance and longer service life. Its core features are:

Structural features

Composed of electromagnetic pilot head, piston and valve body, the area of piston rear chamber is larger than the front chamber, and the pneumatic force ensures sensitive closing state.

Cancellation of rubber diaphragm and pressure spring, the use of high-strength piston structure, significantly improve the durability.

The working principle of Dust Collector Pulse Jet Valve is divided into two stages:

Blowing state: After the signal is inputted by the electric controller, the electromagnetic pilot head opens the unloading hole, and the pressure gas in the front chamber of the piston lifts up the piston and opens the blowing channel.

Closed state: after the signal disappears, the unloading hole is closed, the gas pressure in the back chamber of the piston pushes the piston to reset, and the channel is closed.

Technical standard

Working pressure: 0.2~0.6MPa

Voltage specification: DC24V or AC220V/50Hz

Protection grade: IP65

Working medium: clean air

Applicable temperature: room temperature type -25~85℃, high temperature type -25~230℃.

Life span: 1 million times

Installation specification of Dust Collector Pulse Jet Valve

Sealing Requirements: The threaded connection should be filled with PTFE raw material tape or thread sealant, and the combined surface of the air distribution box should be smooth and clean.

Air source processing: the air inlet pipe of the air distribution box should be installed with a filter and regulator, and the bottom is equipped with a drain valve to ensure that the compressed air is dry and free of impurities.

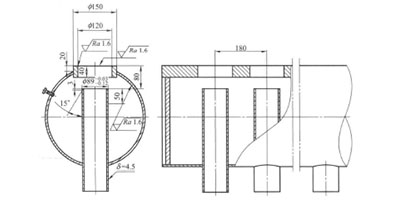

Processing accuracy: the air package installation end face according to Figure 2 processing, to ensure that the size tolerance and surface roughness.

Cleaning Requirements: The air bag and blowpipe should be thoroughly cleaned before installation to avoid residual debris.

Connection

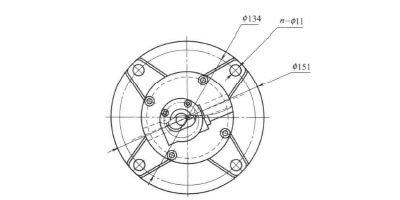

When installing with the round manifold, the dimensions should be according to Fig. 3 to ensure the matching of the connection (e.g. Φ150/Φ120 aperture).

The machining diagram of the manifold connection (Fig. 2) specifies the key dimensions: 180 mm total width, 15° chamfer, δ = 4.5 mm wall thickness.

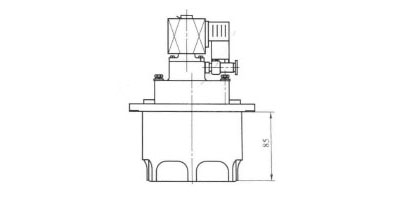

External dimensions

The external dimensions of the 3-inch Dust Collector Pulse Jet Valve are shown in Figure 3, with key parameters such as total length of 134mm and mounting holes of Φ151mm marked.

With compact design and flexible blowpipe arrangement, the valve is suitable for the demand of high efficiency ash cleaning in industrial dust removal system. By optimising the piston structure and electromagnetic control, it achieves fast response and stable operation, and meets the stringent requirements of reliability and precision for export products.

- View as

H-series Pneumatic Pulse Jet Valve

The Starmachinechina105 H-series Pneumatic Pulse Jet Valve manufactured by Qingdao Star Machine Technology Co.,ltd. is the core component of a bag filter. This pulse jet valve has the advantages of compact structure, high dust removal efficiency, low cost, long service life, universal spare parts, and convenient use and maintenance.

Read MoreSend InquiryPiston Type Pulse Solenoid Valve

Qingdao Star Machine Technology Co., Ltd. is a modern scientific and technological manufacturer integrating R&D, production, sales and service, specializing in the production of various types of piston type pulse solenoid valve, pneumatic components and fluid control equipment. The company has a high-quality R & D team and advanced production equipment, with exquisite technology, rigorous quality management system, and constantly provide customers with quality products and services at competitive price.

Read MoreSend InquiryDust Collector Solenoid Valve

Qingdao Star Machine is a professional China dust collector solenoid valve manufacturer and air cleaning valves supplier. The bag type industrial air cleaning solenoid valve ensures continuous operation during dust removal.

The main cleaning methods of dust collector solenoid valve include mechanical vibration cleaning, reverse airflow reverse blowing cleaning, and pulse jet cleaning. Generally, one method is commonly used, and there are also several methods of cleaning ash that are combined. The acoustic cleaning method can be combined with other methods to improve the cleaning effect.

Due to the importance of dust removal collector solenoid valve and its accessories, Qingdao Star Machine has focused on researching the dust removal accessories of bag filters and dedicated to providing fast delivery and high quality dust collector solenoid valves.

Piston Operated Pulse Jet Solenoid Valve

Summary:Qingdao Star Machine Technology Co. Ltd. is one of top ten factories of Piston Operated Pulse Jet Solenoid Valve with our own brand SMCC. We have an efficient and professional team ready to support you. Our goal is to ensure your satisfaction and give you peace of mind when choosing our products.

Read MoreSend InquiryPlunger Membrane Solenoid Valve

The Qingdao Star Machine whole sale Plunger Membrane Solenoid Valve is through a pilot valve to connect the air in the upper part of the rubber diaphragm with the external atmospheric pressure, the compressed air in the upper part chamber of the diaphragm is instantly discharged from the exhaust channel of the valve bonnet, the under part pressure of membrane becomes lower, the plunger moves upwards due to the pressure difference between the upper and bottom compressed air, causing the bottom air flow of the plunger to quickly spray out from the TANK, thereby achieving the goal of dust removal.

Read MoreSend Inquiry