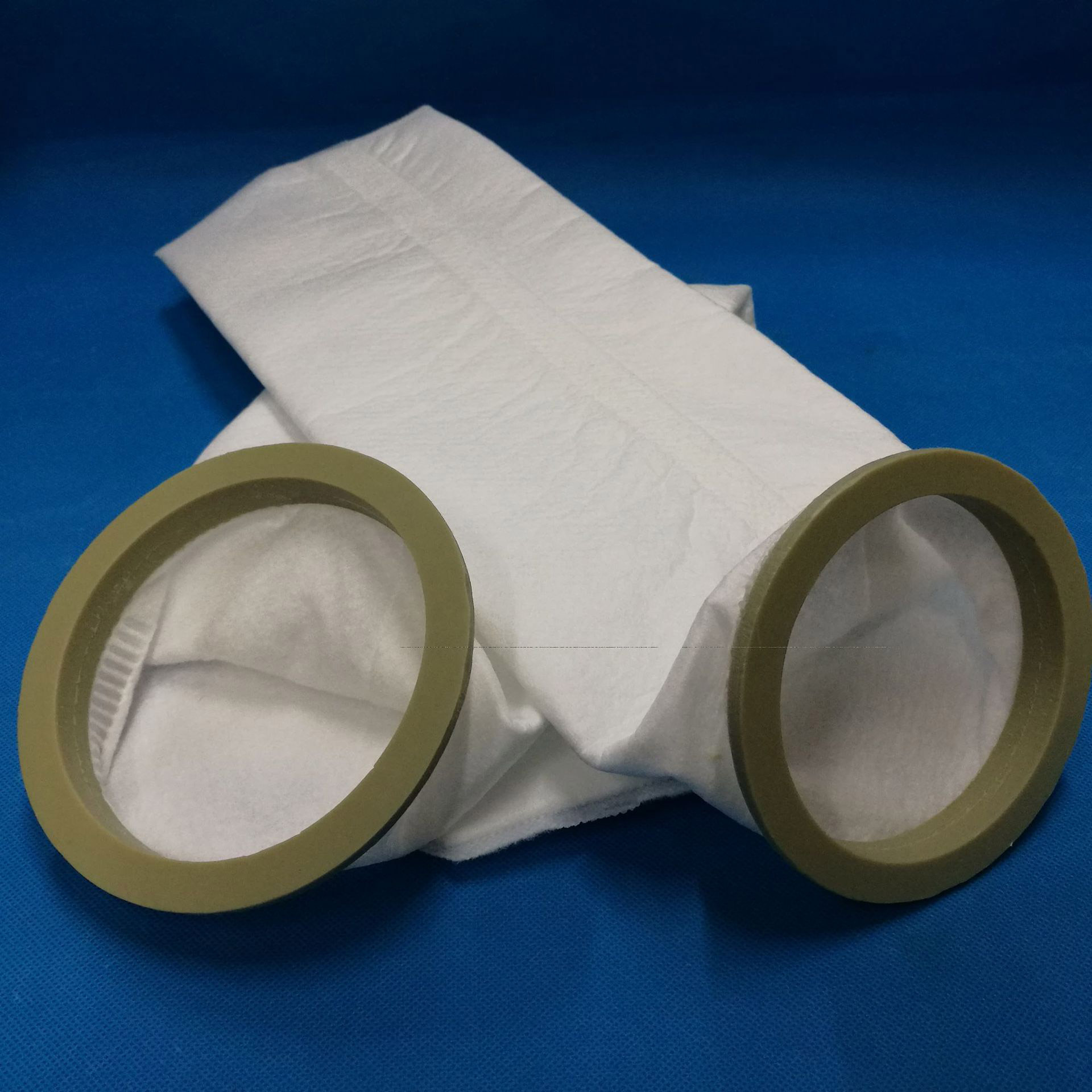

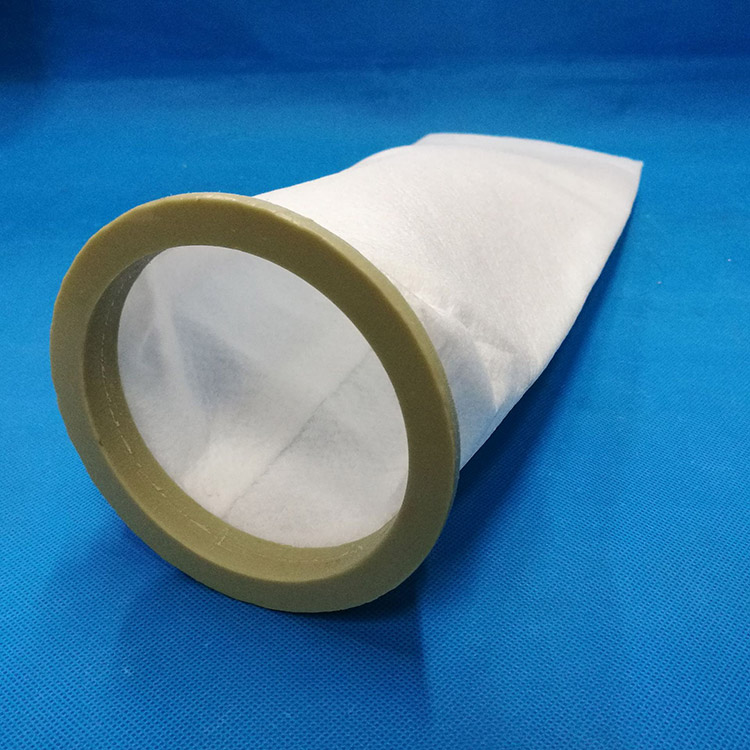

Electroplating Liquid Filter Bag

Send Inquiry

The SMCC high quality Electroplating liquid filter bag can effectively solve the problem of impurities in the electroplating solution, reduce bubbles and fine particles generated after plating. It is important for the filter bag to have good acid resistance since it will often come into contact with acid during the electroplating process. Therefore, the Electroplating liquid filter bag is generally made of PP (polypropylene) which can meet the acid use requirements. Electroplating liquid filter bags can be used with etching machines and developers. These machines and developers are commonly used in the electroplating industry.

Feature

Electroplating liquid filter bag material: polypropylene, polyester, single and double-sided brushing

Supporting equipment: titanium basket

Filtration performance: acid and alkali resistance, high temperature resistance

Adaptation object: electroplating tank anode filtration impurities

The surface of the brushed material is plush, which is good for absorption.

The surface of polypropylene material is smooth and can be moderately cleaned, acid and alkali resistant.

Precision: 0.5~300μm

Usage

Electroplating liquid filter bag can be used in a variety of industries, such as electronics, electroplating industry: liquid crystal display, photolithography, optical discs, copper foil, integrated circuits and other microelectronics and electronic products manufacturing process of a variety of chemicals and treatment, plating solution, process gas purification and purification of gas filtration between;