PET Spiral Filter-press Mesh

Qingdao Star Machine high quality PET spiral filter-press Mesh is a type of belt commonly used in belt dewaterers for press filtration. Our Poleyster spiral Mesh Belt is versatile and can be used in various industries such as papermaking, coal mining, food, medicine, printing and dyeing, and rubber products. They can also serve as conveyor belts and laminating machine supporting mesh belts. Polyester filter-press Mesh ensure the continuous production of modern industrial equipment and significantly improve production efficiency for our customers.

Send Inquiry

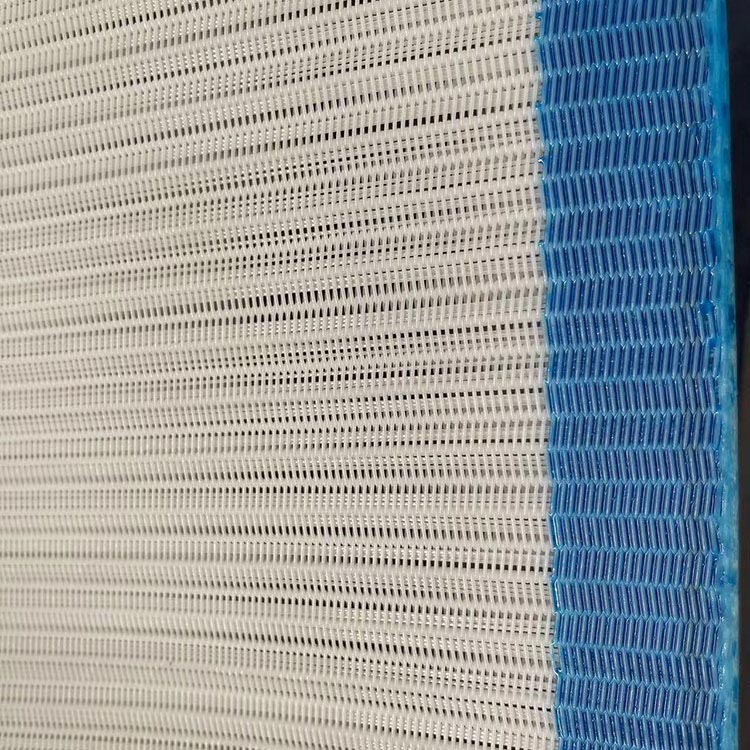

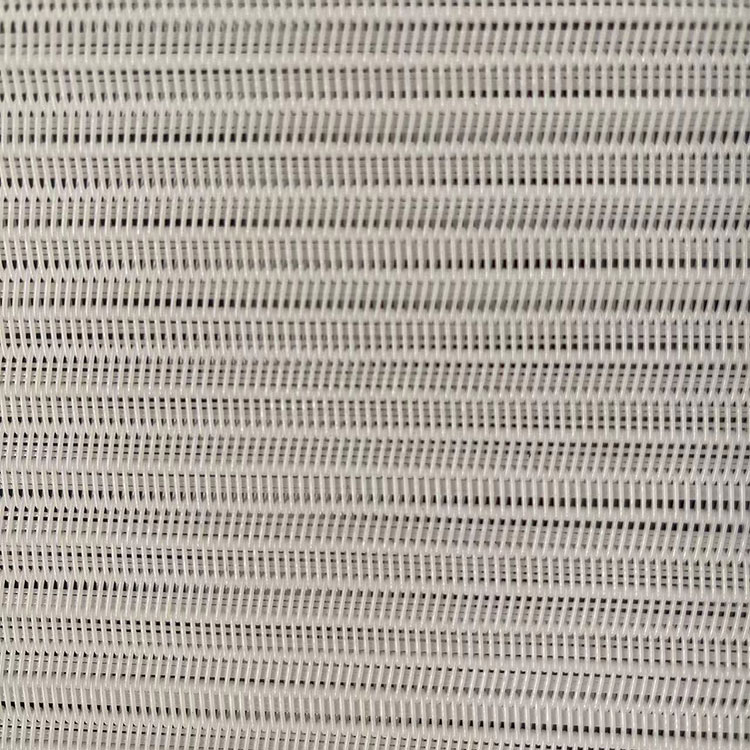

PET spiral filter-press Mesh is created by winding polyester monofilaments into spiral rings and connecting them with weft threads to form a spiral mesh. This mesh has a smooth surface, excellent air permeability, and high temperature resistance. It also features an interface that makes installation easy.

The inclusion of these filler filaments gives the PET spiral filter-press Mesh better press and filter performance. The presence of filler filaments increases the thickness and sturdiness of the mesh belt, which in turn increases the abrasion resistance and durability of the mesh belt during the pressing process.

PET spiral filter-press Mesh is mainly used for press filtration in belt dewatering machines. In belt dewaterers, polyesters filter pressMeshs are used as part of the filtration and dewatering unit. They are responsible for separating the solid particles suspended in the water and removing the water from the solid material through the pressing process to dewater the material.

These PET spiral filter-press Mesh are commonly used in a wide range of applications in wastewater treatment, sludge dewatering, chemical, food processing and other industrial sectors. They can effectively handle large quantities of suspended solids and achieve efficient dewatering and filtration to meet the demand for clean, dry products in industrial production.

Overall, PET spiral filter-press Meshs play an important role in belt dewatering machines and other industrial equipment through their excellent filtration and dewatering properties, helping to achieve efficient solid-liquid separation and material handling.

Product Parameter

| Types of Spiral Dryer Fabric | Wire Diameter(mm) | Strength(N/cm) |

Air Permeability (m3/m2h) |

||

| Warp | Weft | Filler | Area of the surface | ||

|

Large Loop |

0.90 | 1.10 | 0.90×4 | ≥2300 | 10231±500 |

| 0.90 | 1.10 | 0.90×5 | ≥2300 | 6317±500 | |

|

Medium Loop |

0.70 | 0.90 | 0.80×3 | ≥2000 | 10320±500 |

| 0.70 | 0.90 | 0.80×4 | ≥2000 | 8500±500 | |

| Small Loop | 0.52 | 0.70 | 0.68×3 | ≥1800 | 2850±500 |

| Medium Loop (Flat Wire) | 0.70 | 0.70 | (J)0.24*0.85 | ≥2000 | 10100±500 |