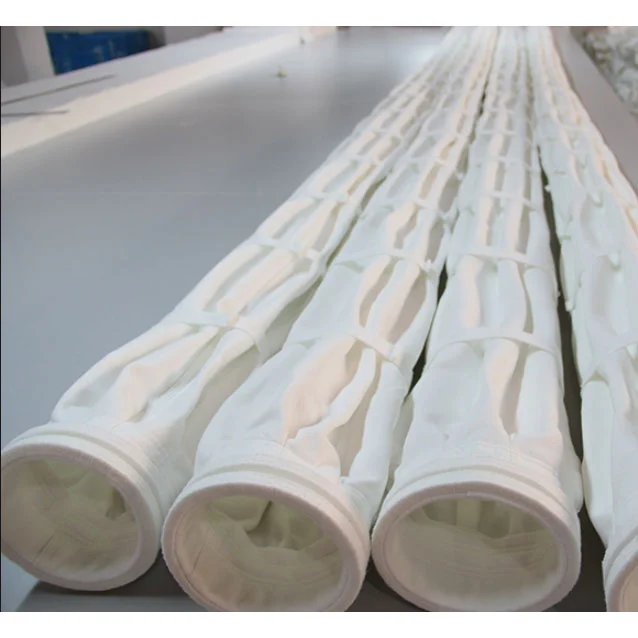

Pleated Filter Bag

Send Inquiry

In order to make the old baghouse meet the new emission standards, it is necessary to modify the old dust collector to reduce the wind speed and increase the filter area of the dust collector. However, the bags of the old dust collectors were used in lengths of up to eight metres, the shells were difficult to retrofit, and the continued use of ordinary filter bags did not increase the filter area of the bags. The use of pleated filter bags allows the plant to maintain the investment in the existing dust collector, but only need to replace the pleated filter bags and the corresponding filter cage, to increase the dust removal effect by 30%, to ensure sustainability.

In addition to low retrofit costs, the use of pleated filter bags has the following benefits.

-Significantly increase the airflow of the existing dust collector to increase the capacity.

The use of pleated filter bags to modify the existing dust collector does not require modification of the dust collector body, direct replacement of the existing filter bags, can increase the system filtration area by 50-150%, is the best retrofit solution to increase the productivity and capacity of the dust collector system.

-Significantly reduce the system operating energy consumption and maintenance costs.

The use of pleated filter bags instead of ordinary round or oval filter bags, the system pressure difference is greatly reduced, the fan energy consumption is greatly reduced; blowing frequency is significantly reduced, so the compressed air usage is significantly reduced, the blowing system component loss is also greatly reduced.

-In the new dust collector using a significant reduction in the dust collector box volume.

The new dust collector uses pleated filter bag instead of common round or oval filter bag, under the same condition of air to cloth ratio, the dust collector box and pulse blowing system can be greatly reduced, which can ensure or improve the efficiency of the system and at the same time, reduce the initial investment in the blowing system and the floor space.

-Dramatically increase the dust collection efficiency of the dust collector, especially for PM2. 5 and PM10 ultrafine dust.

The use of pleated filter bags instead of ordinary round or oval filter bags can greatly increase the system filtration area, which can directly reduce the air-to-cloth ratio, greatly reduce the system pressure difference and pulse blowing frequency, thus greatly reducing the system's dust emissions, especially ultra-fine dust emissions.

-Extend the service life of the filter bag.

The use of pleated filter bag instead of ordinary round or oval filter bag, the unique combination of filter bag and keel completely avoids the fatigue damage to the filter bag caused by the transverse support ring of the ordinary keel, coupled with lower operating differential pressure and blowing frequency, the fatigue damage to the filter bag is greatly reduced, and the service life of the bag is greatly extended.