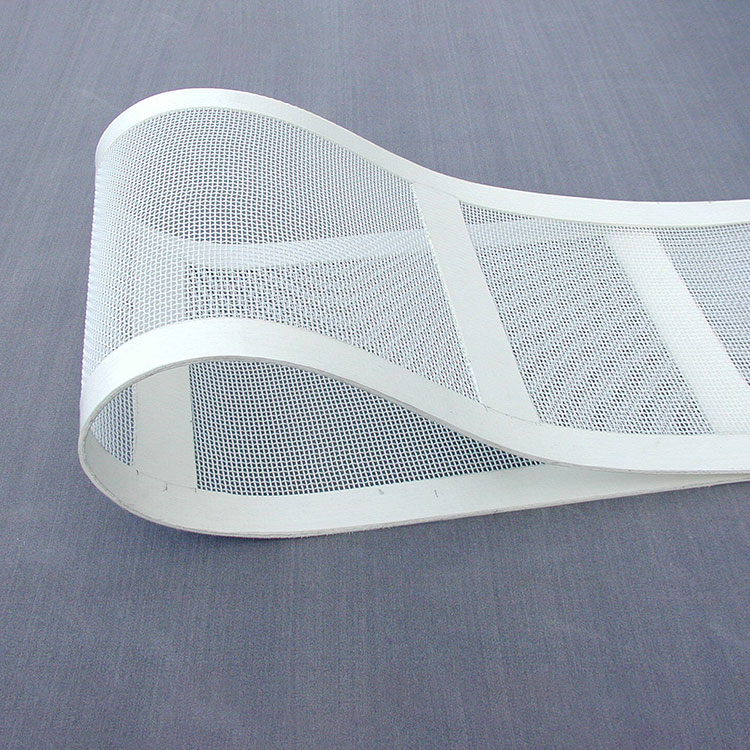

Polyester Spiral Filter Belt

SMCC provides high temperature resistant, breathable, food grade safe polyester spiral filter belts with different models to adapt to different environments, suitable for food processing, papermaking, environmental protection and other industries, the products are made of imported materials, durable and with good filtration effect.

Send Inquiry

Product Introduction

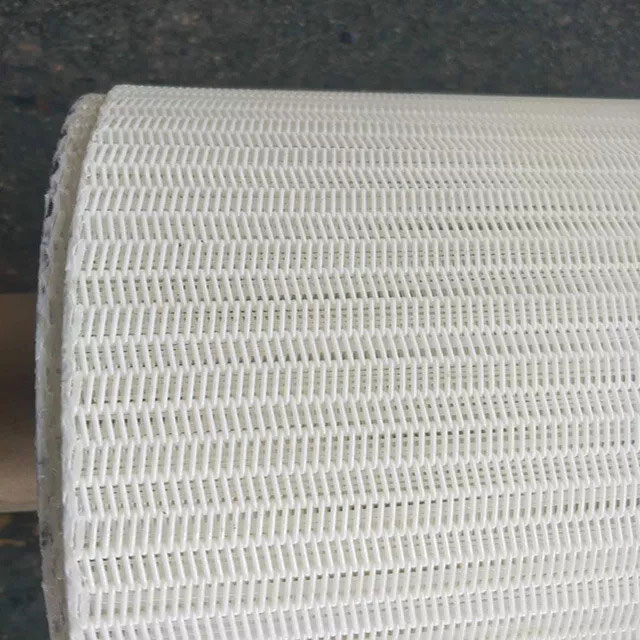

Polyester Filter Spiral Belt (also known as Polyester Spiral Mesh Belt) is a kind of industrial grade filter conveyor belt made of high-density polyester monofilament by special spiral weaving process. Through the seamless connection technology and heat-setting process, the product is characterised by high strength, high temperature resistance and excellent air permeability, which can meet the filtration, dewatering and drying needs of food processing, paper making, wastewater treatment and other demanding industrial scenarios. The core material supports both polyester (PET) and PPS options, with a maximum temperature resistance of 240°C, making it an ideal alternative to traditional metal mesh belts and canvas.

Product Applications

Polyester filter spiral belts are widely used in the following areas due to its unique open mesh structure:

Food processing: fruit and vegetable washing, pasta drying, dairy product filtration, pasteurisation conveying

Paper industry: drying of culture paper/cardboard, dewatering of pulp board, non-woven moulding

Environmental treatment: sludge dewatering, sewage treatment solid-liquid separation

Special industries: UV printer conveying, veneer drying, gypsum board manufacturing

Other scenes: coal mine conveying, pharmaceutical production, rubber products moulding

Polyester filter spiral belt core features

1. Excellent high temperature resistance

Polyester (PET) material long-term resistance to 150 ℃, PPS material temperature resistance up to 240 ℃.

Heat-setting process improves structural stability and avoids high temperature deformation

High efficiency of air and water permeability

2. Seamless spiral weave design for air permeability of up to 10,000 m³/m²h.

Uniform water permeability improves drying efficiency by more than 30%.

Food-grade safety certification

3. BPA-free, chemical-resistant, meets FDA and EU food contact standards.

Smooth and easy-to-clean surface to avoid material sticking

Long service life

4.Hydrolysis-resistant polyester fibre + conductive carbon filament reinforcement process, wear resistance increased by 50%.

Supports hot-melt repair, reducing maintenance costs by 60%.

Flexible customisation service

5.Width 10cm-10m, support any length cutting

Flat wire, round wire, carbon wire and other materials can be selected to meet different load requirements.

Product Process

Raw materials → sizing → weaving → cleaning and inspection → primary heat setting → insertion section → secondary heat setting → finished product packaging

Product Parameters

Polyester Spiral Filter Screen

| Item | Model | Permeability(m3/m2h) |

| Big Circle | LGW4×8 | 16500-19500 |

| Medium Circle | LGW3.8×6.8 | 16500-19500 |

| Small Circle | LGW3.2×5.2 | 16500-19500 |

Polyester Spiral Filter Belt

| Model | Wire Dia.(mm) | Density/CM | Hole Size | Porosity | ||

| Warp | Parallel | Warp | Parallel | mm | % | |

| CXW25254 | 0.22 | 0.25 | 27-28 | 22-23 | 0.144×0.194 | 17.3 |

| 25274-2 | 0.22 | 0.27 | 27-28 | 18.5-19.5 | 0.144×0.256 | 19.4 |

| 27234-1 | 0.20 | 0.23 | 29.5-30.5 | 23.5-24.5 | 0.133×0.187 | 17.9 |

| 27234-2 | 0.20 | 0.23 | 30-31 | 23.5-24.5 | 0.128×0.187 | 17.5 |

| 27254 | 0.20 | 0.25 | 29.5-30.5 | 21.5-22.5 | 0.133×0.204 | 18 |

| 27274 | 0.20 | 0.27 | 29.5-30.5 | 21-22 | 0.133×0.195 | 16.8 |

| 29234 | 0.20 | 0.23 | 31-32 | 21-22 | 0.177×0.235 | 18.7 |

| 29254 | 0.20 | 0.25 | 31-32 | 20.5-21.5 | 0.177×0.226 | 17.6 |

| 31204 | 0.17 | 0.20 | 34-35 | 29-30 | 0.120×0.139 | 17.0 |

| 25358 | 0.22 | 0.35 | 27.5-28.5 | 18.5-19.5 | 0.137×0.176 | 12.9 |

| 25408 | 0.22 | 0.40 | 27.5-28.5 | 18.5-19.5 | 0.137×0.176 | 12.9 |

| 27358 | 0.20 | 0.35 | 29.5-30.5 | 19-20 | 0.133×0.163 | 12.7 |

| 27408 | 0.20 | 0.40 | 29.5-30.5 | 19-20 | 0.133×0.163 | 12.7 |

Polyester Washing Filter Screen

| Model | Density/CM | Wire Dia.(mm) | Hole Size | Porosity | Intensity | ||

| Warp | Parallel | Warp | Parallel | mm | % | N/CM | |

| Xw18302 | 19.6±0.5 | 14±0.5 | 0.25 | 0.30 | 0.260.41 | 29.5 | ≥400 |

| XW18303 | 19.5±0.5 | 14±0.5 | 0.25 | 0.30 | 0.260.41 | 29.58 | ≥400 |

| XW16302 | 17.5±0.5 | 13.5±0.5 | 0.27 | 0.30 | 0.300.44 | 24.97 | ≥400 |

| XW16302 | 17.5±0.5 | 13.5±0.5 | 0.27 | 0.30 | 0.300.44 | 24.97 | ≥400 |

| XW16304 | 17.5±0.5 | 13.5±0.5 | 0.27 | 0.30 | 0.300.44 | 24.97 | ≥400 |

| XW16404 | 17.5±0.5 | 13.5±0.5 | 0.27 | 0.40 | 0.300.34 | 23.9 | ≥400 |

| XW10504 | 20.5±0.5 | 12±0.5 | 0.50 | 0.50 | ≥1600 | ||