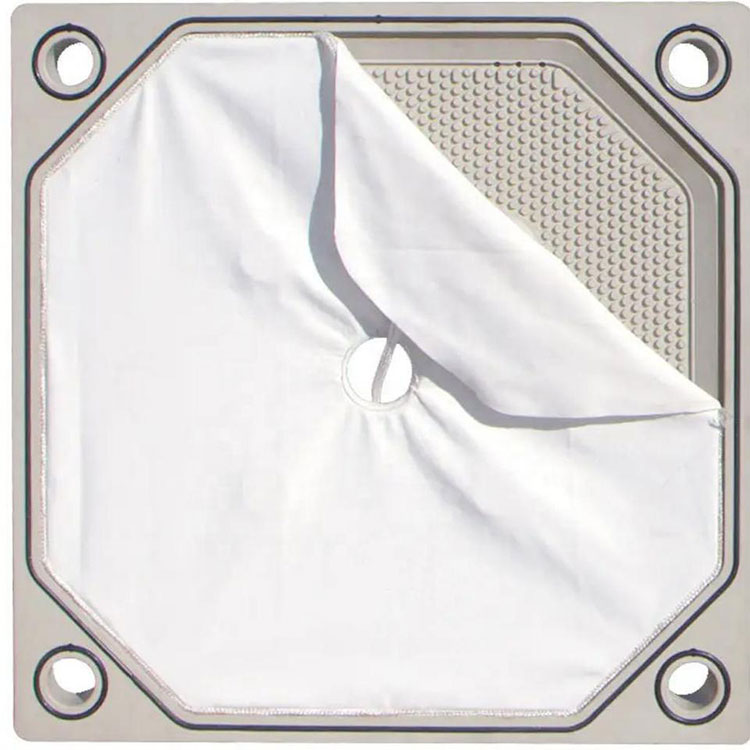

Water Biological Filtration Filter Cloth

Qingdao Star Machine is a professional manufacturer of water biological filtration filter cloth and other series of products, and our water biological filtration filter cloth can be customized. The products mainly include polypropylene, polyester, nylon, and vinylon woven monofilament filter fabrics, and multifilament filter fabrics; Room temperature and high temperature air dust removal and filtration materials. We have a team that combines technical and management talents with advanced production and testing equipment, which has won unanimous praise from users.

Send Inquiry

The customized water biological filtration filter cloths produced by Qingdao Star Machine mainly include polyester filter cloths, polypropylene filter cloths, nylon filter cloths, and vinylon filter cloths.

Material performance of PE water biological filtration filter cloths: acid and weak alkali resistance. Good wear resistance, corrosion resistance, and recovery, but poor conductivity. Polyester fibers generally have a temperature resistance of 130-150 ℃. This product not only has the unique advantages of ordinary felt filter fabrics, but also has excellent wear resistance and high cost-effectiveness, making it the most widely used variety of felt filter materials.If necessary, we can provide free samples.

Product Feature And Application

1. Polyester long fiber water biological filtration filter cloth is made by twisting and weaving fibers, which increases its strength and durability. After special processing, its strength is more than twice that of ordinary filter cloth. Polyester long fibers have a smooth surface, good wear resistance, and high strength. Compared to polyester short fibers, polyester long fibers offer better waterproof performance, stronger wear resistance, and are easier to clean.

2. Polypropylene water biological filtration filter cloth comes in short fiber and long fiber types. Long fibers have higher fracture strength and better breathability, while short fibers provide better pressure filtration due to the wool-like surface. Industrial fabrics made from polypropylene long fibers have a smooth surface, good breathability, and work well for unfiltered powders, improving filtration efficiency.

3. Nylon fiber water biological filtration filter cloth has high strength and excellent elasticity. It has outstanding wear resistance, making it one of the strongest synthetic fibers, even used in automotive tires. Nylon is resistant to strong alkalis and weak acids but is sensitive to sunlight, which can cause discoloration and brittleness. Therefore, nylon filter cloth should not be exposed to direct sunlight for long periods.

4. We also offer vinylon water biological filtration filter cloth. Vinylon, also known as polyvinyl alcohol fiber, is similar to cotton and has the highest moisture absorption among synthetic fibers. While it has good chemical stability and resistance to sunlight, it is not resistant to strong acids and alkalis.