China Wet Dry Vac Filter Bag Manufacturer, Supplier, Factory

Our corporation puts emphasis about the administration, the introduction of talented staff, plus the construction of team building, attempting hard to improve the quality and liability consciousness of team members. Our organization successfully attained IS9001 Certification and European CE Certification of Wet Dry Vac Filter Bag,Dust Collector Filter Bag,Hepa Filter Bag,Vacuum Cleaner Filter Bag, We have been sincerely wanting forward to cooperate with consumers all over the earth. We feel we can easily satisfy with you. We also warmly welcome buyers to visit our manufacturing unit and purchase our products and solutions.

Wet Dry Vac Filter Bag, Taking the core concept of "to be the Responsible". We will redound up on society for high quality solutions and good service. We are going to initiative to participate in international competition to be a first- class manufacturer of this product in the world.

Hot Products

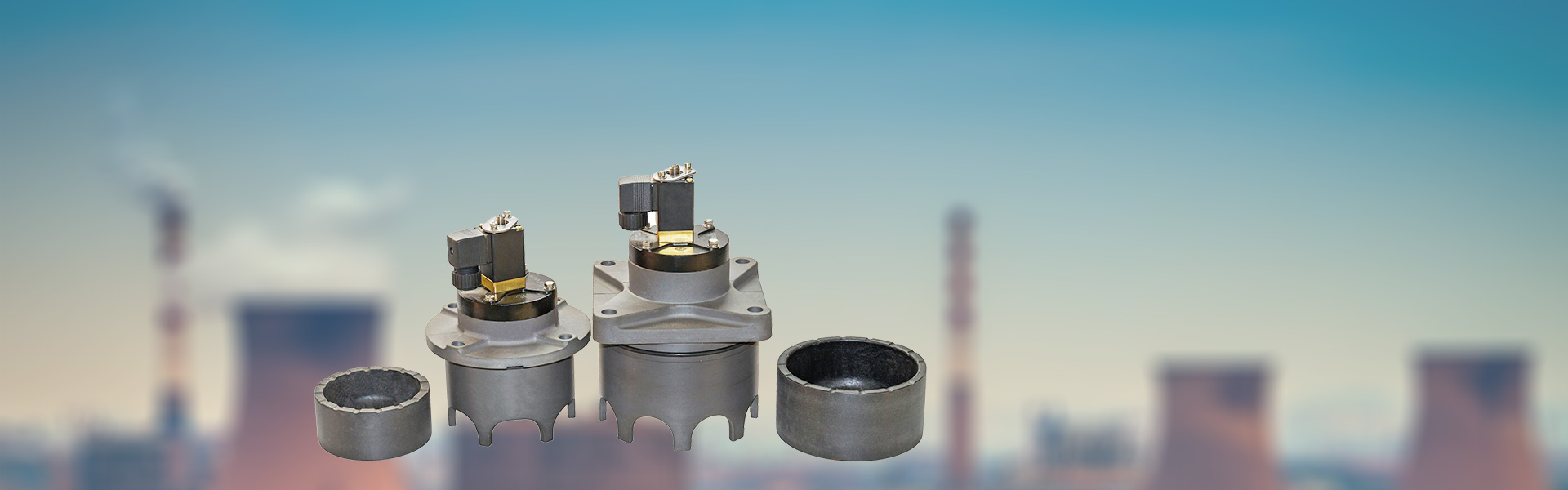

Right Angle Electromagnetic Pulse Valve

Qingdao Star Machine is Right Angle Electromagnetic Pulse Valve supplier with cheap price and top quality.It is divided into three categories: right Angle type, submerged type and straight through type. The air outlet and the air inlet are at a 90 degree Angle, so it is called a right Angle electromagnetic pulse valve.The electromagnetic pilot head of the right Angle electromagnetic pulse valve is generally driven by an electromagnet or double electronically controlled electromagnet, and the pulse blowing ash is realized through the switching pulse valve.Sludge Dehydration Fabric

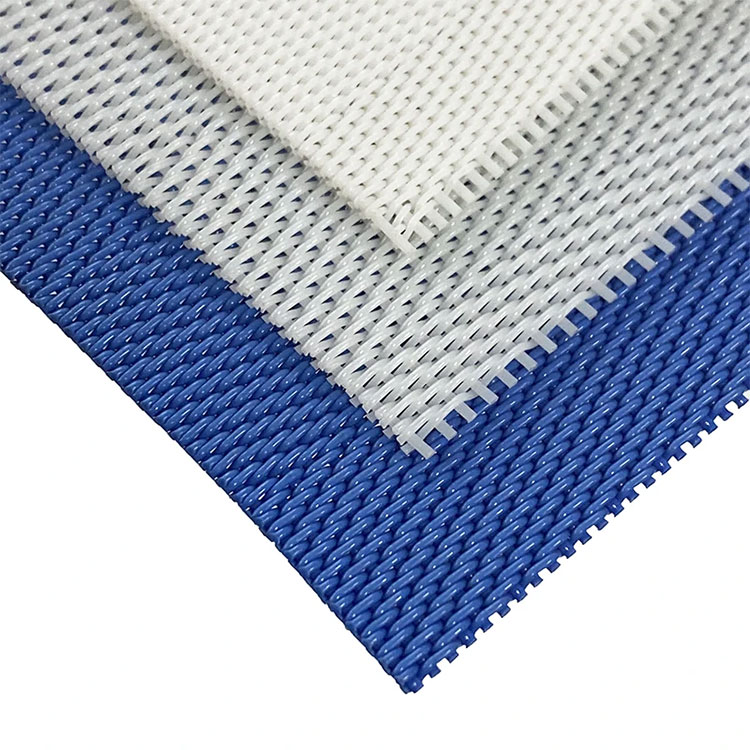

Qingdao Star Machine’s top quality Sludge Dehydration Fabric is also called Press- Filter Fabrics or Polyester Filter Belt ,which is mainly used for sludge dehydration, paper pulp and juice squeeze, mine smelting, mine tailings disposal and other pressure filtration industries.we can offer the sample to test the quality first for your assured procurement.G1 Threaded Pulse Valve

The Qingdao Star Machine G1 Threaded Pulse Valve has an advantages in supply, high quality, low price, fast quotation, short delivery time, and long warranty period.Reliable Piston Diaphragm Valve

The Reliable Piston Diaphragm Valve has a wide range of applications and can be used in a variety of industries such as pharmaceutical, wastewater treatment, food processing, etc.Qingdao Star Machine is the professional manufacturer, we would like to provide you high quality Reliable Piston Diaphragm Valve.220V AC DMF Solenoid Coil

The 220V AC DMF solenoid coil features an enamelled wire wound on a cylindrical core, encased in an injection-moulded exterior. The exposed plug allows for easy connection to a junction box, producing magnetic force when powered. This coil is ideal for use in the solenoid valve sector.Steel Filter Bag Cage

The material of Qingdao Star Machine’s quality Steel Filter Bag Cage is 304 stainless steel, lightweight and strong, high strength, no deformation under pressure, accurate size, avoiding the problems of filter bags contacting each other, bag frame friction, and difficulty in loading bags after being loaded into the dust collector. The bag cage support ring and longitudinal tendons are evenly distributed. Our bag cages have strong welded joints, which will not fall off and loosen. The surface of Steel Filter Bag Cage is smooth and burr-free, after high temperature organosilicon coating treatment to prevent flaking and corrosion.